CHASSIS (SIDE VIEW) - Drawn by hand in half scale - we needed 3 large drafting tables and would put a different view on each table (front - side - top). The grid lines were critical since you had to transfer a lot of dimensions between drawings. The extra cabs were relatively new back then and we loved the ability to scootch that driver back and give them some more room. Note also the high point on the roll cage over the rear axle. I had proposed (to GM) designing our own custom length shocks which would have required a high mounting point. That cost add was around $100 grand (back then) for engineering and building custom shocks and Bilstein was paying $50 K to use their parts ... a $150 K swing in the budget! So ... GM made us stay with the Bilsteins and that drove the design of the "Grasshopper" rear rocker, allowing 21" of travel with modified off-the-shelf 14" travel shocks (the longest available at the time). The Class 7 rules stated "No remote mounted shocks"! So ... we made sure one end was attached to the axle.

CHASSIS (TOP VIEW) - The detail drawings for the shop to build the frame and all of the components were all done in full scale. This allowed the fabricators to literally trace out some of the plates that needed to be cut by hand on a band saw ... pre-laser cutting days! These full vehicle half scale drawings were used primarily for design layouts.

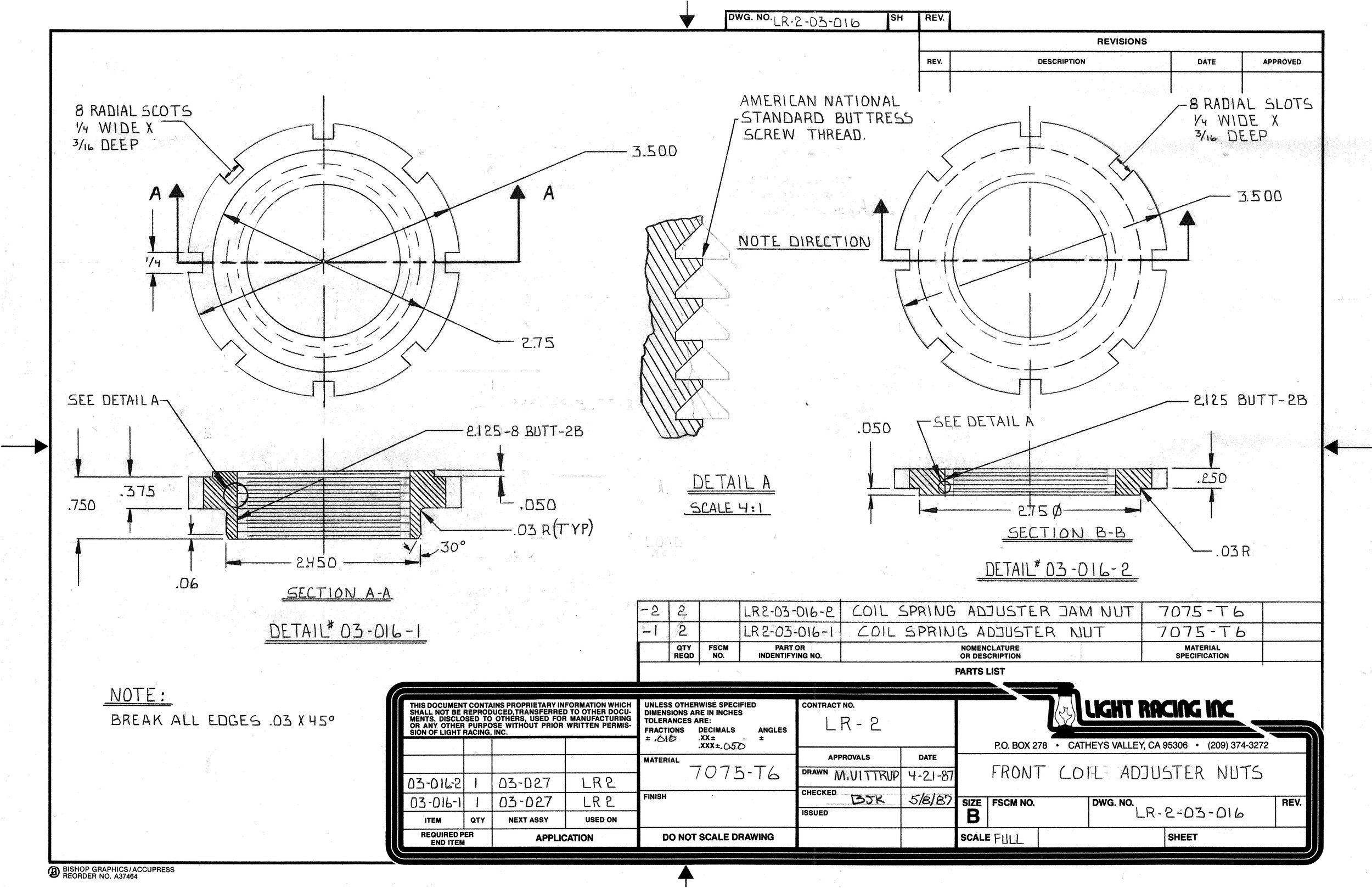

COIL ADJUSTER NUTS - Hand drawn

REAR LEAF SPRING SHACKLES - The SCORE Class 7 rules back in the day required the vehicle to be supported by leaf springs (stock length) in the rear per the production truck suspension type. However there was no rule yet that said you couldn't have other control links! LR-2 used a complete 4 link system for superior axle location control for the 21" of rear travel. Since the axle is normally located by the leaf spring system ... the added 4-Link system would be redundant and result in competing locational forces. This was solved by using articulating tension shackles at both the front and rear leaf spring eyes which greatly reduced any conflicting load paths. This allowed the weight of the vehicle to be suspended by the leaf springs, but the suspension not precisely located by the leaf springs. Note also the 4130 sheetmetal double thin-wall outboard shackle mounts.

REAR LEAF SPRING UPPER SPRING CLAMP - Modeled and drawn by hand in 2D and made from 7075-T6, this lightweight, multi-function mount on the rear of the Larry Ragland Chevrolet S10 accommodated four U-Bolt nuts, three lower shock mount bolts, and one rocker drive link bolt.

FRONT COIL SPRING STACK COMBINATION CHART - CIRCA 1988

All of the 2 stack combos were mapped out in the chart shown here for easy reference out on the track during testing.

SHEET METAL TRUSSED REAR AXLE HOUSING

When is the first time you saw a 4130 Chromoly sheet metal trussed rear axle housing? This high modulus light weight construction used largely .063" and .050" sheet, flared holes, and capped double thin wall - double shear link mounts. Used on the Chevy S-10 Class 7 driven by Larry Ragland. This truck won it's first race (1987 SCORE/Riverside Off-Road World Championships), was SCORE/HDRA Class 7 champion in it's first season, won the 1988 SCORE/Riverside Off-Road Class 7 Championship, and finished every race mile of every race entered as a GM Chevy factory entry.